Cetus series digital ink jet printers’ dual paperboard printing mode supports two paperboards printing at the same time to increase productivity. In Dual Paperboard printing mode supports paperboard dimensions from minimum of 600mm×600mm to maximum of 1200mm×1350mm. In the single-paperboard printing mode, Cetus series digital inkjet printers support corrugated paperboard printing dimensions is up to 2000mm×4000mm.

Cetus series digital inkjet printers are equipped with a transport unit comprising of several vacuum belts that effectively absorb paperboards; precision servo control on belt movement.The vacuum system is consisted of eight individual control zones for positioning paperboards of different specifications and dimensions.

Cetus series digital inkjet printers’ dual-roller mechanism s hold paperboards securely onto the printing platform, ensuring steadiness of paperboards throughout the printing process to complete high-quality printing.

The automatic deviation rectification function ensures consistency of printed zones and accuracy of die cutting.

Standard configuration is CMYK 4 colors, upgradable to CMYKOG 6 colors by added OG colors to expand the color gamut.Greyscale printheads are adopted with a minimum ink droplet volume of 5pl and a maximum printing resolution of 600×1200 dpi.

Smart negative pressure control system equipped with a digital pressure meter ensures high-quality printing of the industrial-grade piezo greyscale printheads at the maximum ignition efficiency.

Cetus series digital inkjet printers adopt an advanced stable printing system that effectively prevents the formation of bubbles that impede nozzle performance to secure stable and reliable printing quality.

Adopts an integrated and compact structure design, to carry out major nozzle maintenance steps automatically, such as ink purge; wiping and capping to minimize nozzle damage risks and ensuring stable and reliable printing performance.

Professional ink droplet volume control technology exhibits smooth transition, vivid image and small-font text with clear and sharp edges.

| Technical specification: | |

|---|---|

| Printhead Type | Ricoh GEN6 |

| Number of printheads | 36 |

| Color Ink | C/M/Y/K/O/G |

| Resolution | 600×300dpi;600×600dpi; - 600×900dpi;600×1200dpi |

| Color mode | Symmetrical color sequence |

| Color sequence | O/G/Y/M/C/K/K/C/M/Y/G/O (orange, green, yellow, magenta, blue, black) |

| Ink type | Water-based ink |

| Printing method | Scanning |

| Head Gap | Adjustable, up to 38mm |

| Media type | Corrugated paper |

| System components: | |

| Conveyor belt | vacuum belt |

| Belt width | 2000mm |

| Printer software | POS |

| RIP software | Agfa Asanti |

| Board Loading mechanism | Automatic |

| Board Unloading mechanism | Automatic |

| Belt drift tracking | Automatic |

| Loading method | Singe sheet, Dual sheets |

| Ink supply method | Automatic ink supply |

| Degassing method | Degasser + ink circulation |

| Equipment specifications: | |

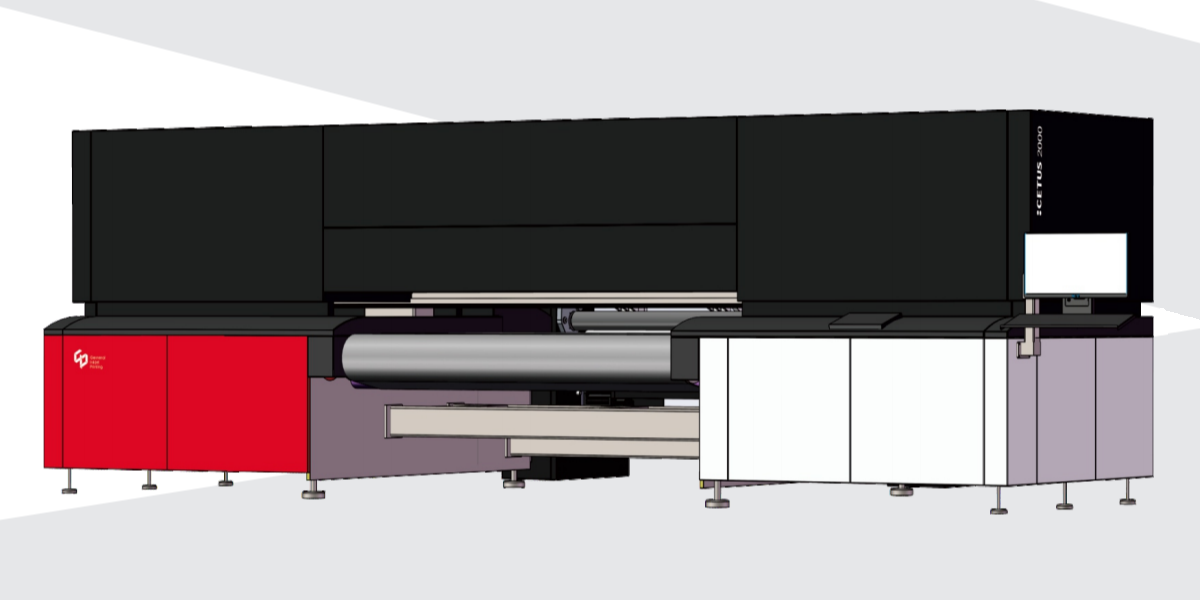

| Equipment dimensions | 6m(width)×3.8m(depth)×1.98m(height) |

| Equipment weight | 4 tons |

| Total power | 20KW |

| Advantages: | |

| Vacuum belt table | - |

| Automated Loading | - |

| Belt drift tracking | - |

| Symmetrical color sequence printing | - |

| Linear motor | - |

| Steel beam structure to reinforce stability | - |

| Non-contact type ink scraping | - |

| Automated spitting | - |

| Full servo motor control + PLC control | - |

| Movable collection unit + palletizer | - |